FIP Journal - Volume 9

Intimidator Nex Gen Double Cementer

Greg’s Equipment Update

The need to find continued improvements for efficiencies are being requested by our clients for operations ranging from longer Laterals, Horseshoe Wells, Slim-Hole, and Faster Displacement Stages. Depending on the stage design (s) displacement may range from 30% to 40% of the operation. Freemyer Industrial Pressure LP. custom engineered solution is ideal for these conditions with the multifunctional “Intimidator” Nex Gen Double Cementer.

Here are some highlights for the “Intimidator” units currently in production. These units will be completed soon and out in the field to serve basins in the USA; however, this design is also ideal for international operations needing to find an improved solution compared to conventional designs.

Multifunctional “Intimidator” Nex Gen Double Cementer with Higher Pressure, Higher Rate & Faster Displacement Capabilities - Combined:

Manufacturer Freemyer Industrial Pressure, LP.

Increased deck engines rated at higher HP compared to others on the market – emission compliant with no diesel exhaust fluid.

Each engine has a redundant hydraulic system and eliminated a third auxiliary hydraulic engine or hydraulics powered from PTOs on Deck Transmissions

Mixing Tank capacity is 30 bbls – 7 bbls mixing side and 23 bbls averaging side

Equipped with four (4) centrifugal pumps with redundancies in recirculation / boost and mix water / water load pumps.

Each centrifugal pump has a state-of-the-art flexible coupling for longevity and help when cavitations exist

Equipped with two (2) non-nuclear densitometers – mixing densitometer and downhole densitometer – to monitor density at mixing tub and downhole in addition densitometers plumbed to serve as backup

Control System with mix water valve control, dry cement inlet control, tub level, real time data acquisition for remote monitoring and parameter exporting for 3rd party systems

Greg - VP

I'm Michael Metzler, and I've proudly served as part of the inside sales team at Freemyer Industrial Pressure (FIP) since 2014. Over the years, I've had the privilege of assisting numerous oil field service companies with their parts requirements, and I'm excited to share how we can help you with your parts needs too.

What sets FIP apart is our commitment to providing personalized support to our customers. As your dedicated inside sales representative, I'm here to assist you every step of the way. Whether you're struggling to identify a particular part or need assistance with sourcing hard-to-find components, I have the expertise and resources to help you find the right solution quickly and efficiently.

Moreover, FIP has cultivated a robust network of suppliers and partners, allowing us to procure parts swiftly and cost-effectively. This means that you can rely on us to deliver the parts you need, when you need them, without compromising on quality or overpaying. Additionally, with access to expert mechanics and electricians, we can provide creative solutions to your equipment challenges, ensuring that you can maintain productivity and minimize downtime.

With decades of experience and expertise in the industry, FIP understands the unique needs of oil field service companies. Our goal is simple: to help your operation stay productive and cost-efficient. By partnering with us, you can trust that you're getting top-quality parts and exceptional service every time.

So, if you're looking to elevate your operations and maximize your return on investment, look no further than Freemyer Industrial Pressure. Whether you need everyday parts or specialized components, I'm here to assist you. Feel free to reach out to me directly at Michael@indpress.com to discuss your parts needs.

Together, let's drive success and efficiency in your operations with Freemyer Industrial Pressure.

Pioneering Sustainable Solutions

I'm thrilled to be part of the innovative team at Freemyer Industrial Pressure LP, where I serve as Lead Mechanical Design Engineer. Here, we're passionate about developing cutting-edge solutions for the oil and gas industry, with a strong focus on sustainability.

Our recent project, the 'Gunslinger Dual Electric Blender', exemplifies this commitment. This unique patented invention aims to reduce carbon emissions through advanced electric technology. This project has been a fantastic learning experience, allowing me to collaborate closely with all our talented departments.

Freemyer's leadership also plays a vital role in our success. Heston Starkey, Operations Manager, provides invaluable guidance with his extensive industry experience, ensuring a smooth transition from design to market launch. Greg Leos, Vice President, leverages his technical expertise and business acumen to keep Freemyer's products at the forefront of innovation. Lastly, Len Freemyer, President, and Owner, is a true visionary leader who inspires us to push boundaries and achieve market leadership.

As Design Lead, I have the privilege of working cross-functionally with fabrication, mechanical & electrical engineering, purchasing, logistics, operations, and sales teams. This collaborative approach ensures our designs are not only innovative but also feasible to manufacture and integrate seamlessly into existing workflows. Additionally, I manage relationships with vendors and suppliers, ensuring we have the resources needed to bring our ideas to life.

Freemyer is continuously developing new solutions that will revolutionize the oil and gas industry. These upcoming innovations will provide a significant advantage to our clients, further solidifying Freemyer's position as a leader in the field.

I'm incredibly proud to be part of this dynamic and innovative team at Freemyer Industrial Pressure. Stay tuned for exciting developments to come!

Freemyer's upcoming innovations hold immense potential for further advancements within the oil and gas industry. I'm excited to be a part of this journey and contribute to a more sustainable future. Siva Kunchala – Lead Engineer

Volume 8 Maintenance Bulletin 2024

Frac Pumps with Cubed Radiators

Power End Lubrication

Stick’s Box

On the subject of Power End lubrication, I want to touch on bearing shells. Although there are a few different styles of bearings in a Power Frame and surfaces that need lubrication, I'm just going to focus on bearing shells of the rods, which are typically the most worn items in a Power End.

A shell bearing with adequate oil pressure and sufficient clean oil flow will last indefinitely. What makes them fail? Uncommon failures happen from mixed oils or dilution. Normally, failures arise from the lack of proper filtration introducing particles into the oil system, leading to premature wear on the lubricated side of the bearing. This will also be reflected on the surface of the crank.

Another cause is heat acting upon the oil, rendering it incapable of carrying any load. The force exerted on the rod compels the bearing surface into the rod journal.

Aerated fluid is the silent killer, passing virtually undetected due to the time lapse between failure and getting the unit back to the facility for inspection.

The other silent killer is scuffing over time when the unit is engaged into gear, and the treating line has treating pressure on it. Normally, a gear range is selected, the driveline is in a stalled state, and then RPM is given, initiating the rotation of the driveline, and overcoming the force needed to turn the power end. It is at this point that scuffing typically occurs. Compounded with every job over time, premature wear is imminent. This can be observed at bearing inspection intervals set by the duty cycle of the unit.

I have seen start-in pressures as low as 25 psi at operating oil temp. The wedge of oil protecting the bearings at this point is virtually nonexistent. Ensure your systems are sized, and the pressure is set for these conditions. Because rated speed oil pressure is significantly higher than start-in oil pressures, I aim for at least 75 psi at idle when hot.

The filtration on these components doesn't have to be exotic; it just has to maintain a cleanliness level and handle the flow through its usable service life. On a small note, check the bypasses and ratings on the filtration you have; you may be introducing contaminants into the system. I typically don't run bypass filtration, but I've found a significant amount bypassing at startup and during operation. Heston Starkey – Ops Mgr

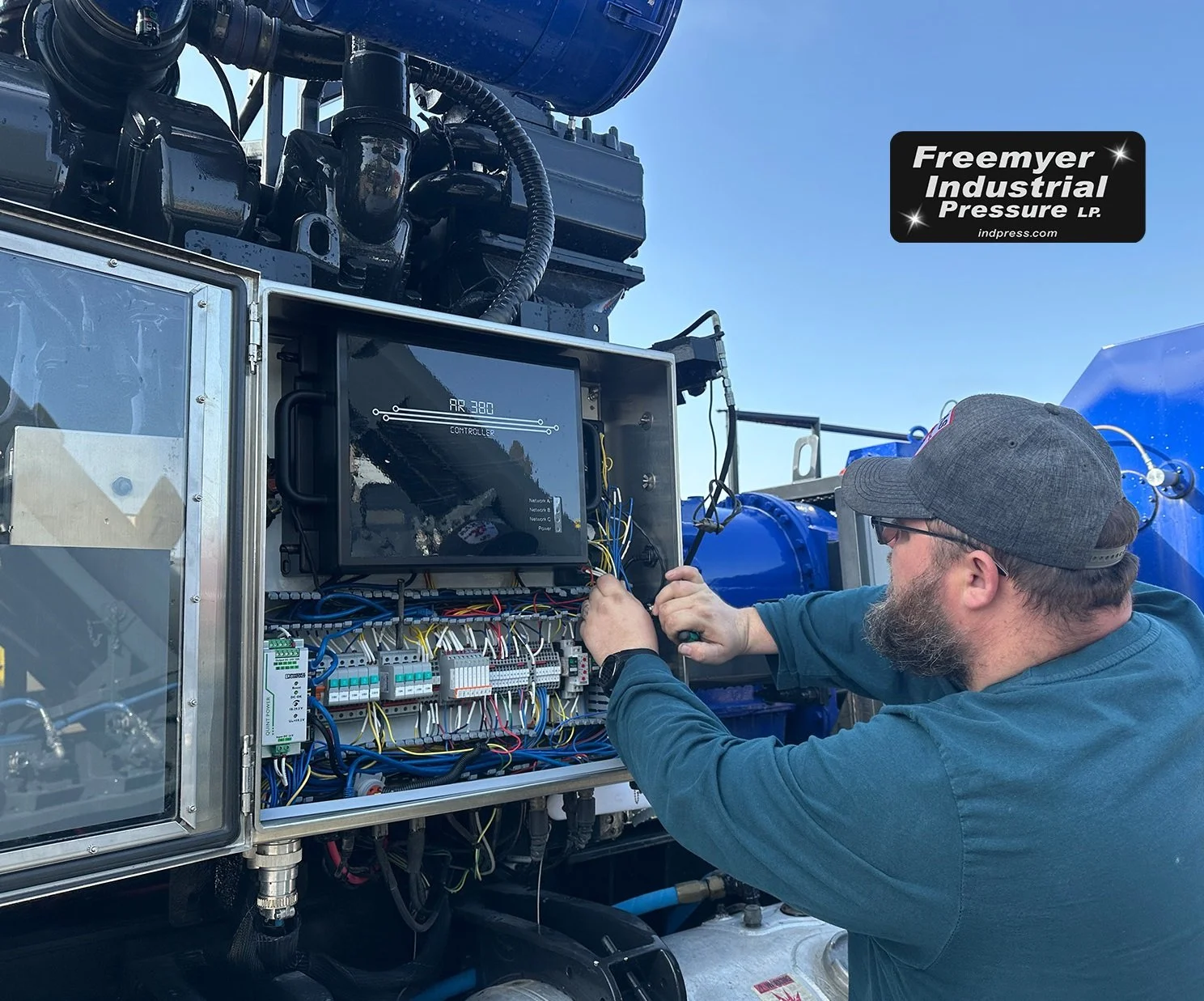

Tony – FIP Lead ET & Trainer

Technology is ever evolving. If you do not stay up to date on the latest advances, you get left behind. That is what we strive to achieve here at Freemyer Industrial Pressure. Keeping up with the newest technology is of great importance and allows us to not only stay ahead of the game but also to put out the best equipment in the industry. Another very important aspect of Electronics, is ease of use. Operators prefer to run equipment that has easy to use, and understand, controls. The tricky part is to build controls that are very easy to operate without losing functionality.

The controls we build are a perfect balance between being user-friendly and functionality. This not only pertains to the software side, but also the hardware side. A technician needing to troubleshoot an issue does not want to open the control of the controls box and see what looks like a spilled pot of spaghetti. That is why the control boxes built here are neat and orderly, with wire labels on every wire and easy to access components. I am constantly making changes to limit the number of fail points and eliminate any extra or redundant components. The last item you should know about is perhaps the most exciting. With the ability to connect and run the unit wirelessly, you will no longer have to drag heavy cable through dirt and mud every time you rig up or down. This also allows your customers to connect and monitor the important data of a job while it is being pumped.

Our number one priority is YOU, the customer. We have the flexibility in our controls to meet your every need. We build each control system as if we were going to be running it ourselves. “Every job is a self-portrait of the person who did it. Autograph your work with excellence.” - Tony

Volume 7 Information Journal 2024

Fully Refurbished Frac Unit with boost centrifugal pump

Fully Refurbished Frac Unit with Centrifugal Boost Pump

Greg’s Equipment Update

The New Year is upon us, all the best to everyone in 2024.

Currently in production we have New Fracturing Equipment and New Next Generation Cement Equipment. Some of this equipment is staying in the USA with many projects destined for International Operations. We will feature those projects and comment further regarding solutions implemented as those projects are completed.

Full refurbishments are still very active with approximately 13,500 HP units nearing final completion with another 13,500 HP on deck for restoration. These assets were underutilized in the current state and FIP performed a deep restoration needed for today’s operational requirements. As shown in the picture provided, those upgrades included the addition of a 3rd axle for weight distribution and bridge laws. New hydraulic systems to include installation of hydraulic powered centrifugal pump along with all the other tasks associated with a restoration of this level – powertrain inspections / repairs, power end and fluid end repairs and or replacements, new hosing for all circuits, and new control system.

We have over 54,000 HP in fracturing / pumping units on our properties, which will make good candidates for fleet addition or refurbishments. We also have slots available to restore your existing equipment to fit current job requirements. Please contact us today to discuss what may be on the horizon for 2024. Greg Leos - VP

Stick’s Box

For years, I have studied pumping units from various manufacturers, either on the yards at districts, traveling to and from the jobsite, or at repair facilities. I have always wondered the same thing over and over: Why is the power end a different color, or looks different? Most of the time, it's because the power end has suffered a failure and had to be replaced.

I then look ahead and give the lube tank a glance; normally, what I see is disheartening. Minimum size, sometimes smaller. From this point, I am curious and want to inspect the whole system. How imbalanced is this system? How undersized? What filtration and how much are they running? Where are the vents located, are they even there? How's the cooler circuit laid out? The questions go on and on, most are answered easily from a quick visual. Where does the system start? At the reservoir. And all eyes should be on that piece of hardware anytime there is an issue or failure.

How is the internal design? The sump area? What size is the tank? It’s a simple system, starts at the reservoir, ends at the reservoir. You will be surprised at how easily something that holds fluid can negatively affect the most abused part of the pumping unit instead of helping it. I always size up from what may be recommended from the manufacturer. The tank and internal baffling should be highly scrutinized. Fluid, GPM, venting, sump, all affect the performance of the reservoir. It's not just a box for lube oil. (continued on page 2)

Letter From Len

We made it through another year without too much excitement, and this new year seems to be staying the same. Let us help you lower costs with our rebuilds, new units, and the used ones we have in stock. We have nearly 50,000 HP in inventory, including a couple of rebuilt 120-barrel blenders and other support equipment.

We will do our best to lower your costs through our strategic buying of components and the efficiencies in our shops. Our team is the best, and they want to help you succeed.

No doubt, it will be an interesting election year, and who knows yet what that may bring to all of us. It could be a terrific fall, and 2025 might be the best ever. Let's get ready and run with it. Len Freemyer - President

QUICK HITS

History:

It’s in the Name:

Enco name was dropped due to its unfortunate meaning of "stalled car" in Japanese.

In 1971, TIME reported that Humble would be renamed Exxon U.S., and Standard Oil of New Jersey would become Exxon Inc. The decision reflected the company's recognition that existing brands could have a global presence. The Enco name was dropped due to its unfortunate meaning of "stalled car" in Japanese. In 1999, ExxonMobil emerged as the result of a merger with Mobil Oil. – AOGHS

“Stone Drill” Patent:

Peter Sweeney from New York City secured a U.S. patent for a "Rock Drills" design, incorporating key elements of the modern rotary rig. Described as a construction suitable for deep well boring, Sweeney's innovation, an improvement on Robert Beart's 1844 British patent, featured a roller bit with replaceable cutting wheels. By giving the head a rapid rotary motion, the wheels cut into the ground or rock, producing a clean hole. The rig's "drill-rod" was hollow, connected to a hose for the introduction of steam or water, facilitating the discharge of dirt and dust from the hole's bottom. - AOGHS

Stick’s Box Continued from page 1

I simply look at the power end fluid reservoir like this: First, I want it to trap and hold all the trash and debris the rotating group (power end) generates or brings in through seals, and vents, in an area separate from the oil I am shuttling through the reservoir. Secondly, I want it to allow all the entrapped air to escape from the lube oil and not send it back through the system regardless of fluid temperature or viscosity. And third, I don’t want the tank design to induce windage or vortexing of the fluid regardless of GPM flow and viscosity of the fluid. If a kidney loop is used, extra caution is needed because it will amplify the failure rate of a poorly designed system.

These systems are not exotic; they are simple. Unfortunately, due to poor systems, Power End replacement is viewed as commonplace, just part of it. I believe in longer component life and putting money where it benefits most, not buying components that are prematurely failing because of a simple overlooked storage tank or mediocre lubricating system. Heston Starkey - Ops Manager

Let Us Help With All Your New Or Used Equipment Needs

Over 50,000 HP is available on our properties, including Frac Pumps, Blenders, and other Support Equipment.

Ten (10) Trailer Mounted

•Radiator Assembly

•Cummins QSK 50 Engine

•Twin Disc 8500 Series Transmission and Torque Convertor

•Power End Assembly

•Fluid End Assembly

•Power End Lubrication

•Packing Lubrication

•Ask about our additional available pump configurations

Additional Equipment Includes:

Four (4) double cement pumping units available for purchase “As Is” or we can rebuild.Currently available: chemical Units, Nitrogen Unit, Data Vans, Manifold Trailers, and Iron Trailers.

By collaborating with FIP, we can effectively help reduce your costs and make well-informed decisions that will have a positive impact on your financials.

Let Us Help With All Your New Or Used Equipment Needs

FIP

Electric Solutions - REDEEM GREEN®

Fracturing

Stimulation

Cementing

Specialty Pumping Units

Electronics & Data Acquisition Solutions

Offshore Solutions

Pumps for CTU Support

Rebuild, Refurbishment, Restoration

After Sales Support

Fire Suppression Systems

+1.817.548.5010

December Information Journal 2023

Double Cementer with Redundant Hydraulic System

Twin Cementer with High Rated Engines and Redundant Hydraulic Systems

Greg’s Equipment Update

Recently deployed Double Cement Pumping Units and more units in production, are equipped with Freemyer Industrial Pressure, L.P. Control System. Our system enables operators to use the intuitive control system in manual or automatic mode. In automatic density mode, the engineered software solution will control the mix water valve, dry cement inlet valve, tub level, and reference desired density setpoints and job design to calculate requirements and automatically adjust.

Real-time adjustments can be made while in automatic mode to density setpoints and overpressure trips. Additionally, real-time data acquisition is configured for wired and wireless remote monitoring. The third parameter exporting capabilities allow for data transfer to third-party system design modeling software or end-user acquisition systems. Post-job reporting, along with cloud sharing, are other features the system has built in.

Please contact us to schedule a demonstration or to discuss how we can install or upgrade your existing equipment with the FIP Control System.

Greg Leos - VP

Stick’s Box

"Running to failure" is a term used in equipment, and it has various meanings, all leading to the same results. The goal of the game is to beat the term. Running to failure in a reactive atmosphere happens very quickly; equipment in the field has issues, but it's never communicated and corrected. Upkeep isn't scheduled accordingly with time allotted for proper repairs. Equipment in the yard isn't given the time needed for proper upkeep, and the run-to-failure time narrows.

Practicing maintenance in a proactive environment and using predictive practices is much more beneficial for the complete component's life. The cost per operational hour decreases, and equipment utilization increases. It's not hard to get there; it's practicality.

The levels of maintenance for all the systems can be overwhelming but manageable. Stay on top of sampling all packages on a unit, get the most out of your maintenance for your dollar. Stay proactive; that way, you can concentrate more effort on the things that are costing or hurting the company the most and beat the term. And yes, it's actually very easy. Heston Starkey - Ops Manager

Letter From Len

Tunnels to Towers:

This past Wednesday, I was honored to be invited to the opening event of housing for homeless Veterans, in Houston. I also had the opportunity to meet Frank Siller, the founder of Tunnel to Towers Foundation.

You are probably familiar with them; they pay off mortgages for fallen Veterans and First Responders. Additionally, they build smart homes for those that have been damaged severely on the job or in war and unable to live in a regular house. What a great organization! An impressive 95% of donations go directly to the cause, which is unheard of in our world today.

I wanted to share this with you and also express my gratitude to Tunnels to Towers for making a difference in so many lives. Len Freemyer - President

QUICK HITS

History:

“Golden Rule” Jones”:

Samuel M. Jones, founder of Acme Sucker Rod Company in 1892, patented a rod design in Toledo, Ohio, solving the issue of broken rods in the oilfield and making him a millionaire. Previously working in various roles in Pennsylvania's oil region, known as "Golden Rule" Jones, he improved workplace conditions and served as Toledo's progressive Republican mayor from 1887 until his on-the-job death in 1904. – AOGHS

Salt-Dome Oilfield discovered in Texas:

In Batson, Texas, a well drilled by W.L. Douglas’ Paraffine Oil Company yielded 600 barrels of oil daily at 790 feet.

Another well, two months later, produced 4,000 barrels a day from 1,000 feet deep.

Together with Spindletop, Sour Lake, and Humble, Batson played a crucial role in establishing the foundation of the Texas oil industry, marking the beginning of Gulf Coast oil exploration. - AOGHS

Equipment Solutions

FIP takes great pleasure in providing exceptional unit upgrade services and solutions.

FIP Control System, which includes mixing water valve control, dry cement inlet valve control, tub level monitoring, and real-time data acquisition for remote monitoring.

Additionally, it provides parameter exporting for third-party system design modeling software.

By collaborating with FIP, we can effectively help reduce your costs and make well-informed decisions that will have a positive impact on your financials.

Image above

By collaborating with FIP, we can effectively help reduce your costs and make well-informed decisions that will have a positive impact on your financials.

Let Us Help Will All Your New Or Used Equipment Needs

FIP

Electric Solutions - REDEEM GREEN®

Fracturing

Stimulation

Cementing

Specialty Pumping Units

Electronics & Data Acquisition Solutions

Offshore Solutions

Pumps for CTU Support

Rebuild, Refurbishment, Restoration

After Sales Support

Fire Suppression Systems

August - September Information Journal 2023

Double Cementer with Redundant Hydraulic System

Twin Cementer with High Rated Engines and Redundant Hydraulic Systems

Greg’s Equipment Update

The need to improve underutilized equipment is still ongoing and will continue as operations demand more power, and increasing efficiencies are a necessity.

We are currently in the final stages of completing several Double Cement Pumping Units. This project involved existing legacy equipment that is now considered underpowered and was underutilized. This deep restoration included utilizing the existing chassis and triplex pump assemblies. Our engineered solution, similar to what was previously mentioned in April, was an ideal fit.

These units are now equipped with two (2) higher-rated diesel engines. Each engine has a redundant hydraulic system to help eliminate interruptions to mixing operations and increase efficiencies. Other upgrades included plumbing redundancies, an additional centrifugal pump, two (2) densitometers (mixing densitometer and downhole densitometer).

A new operating system has been installed - the FIP Control System with mixing water valve control, dry cement inlet valve control, tub level, and real-time data acquisition for remote monitoring; and parameter exporting for third-party system design modeling software.

These Double Cement Pumping Unit fleets will be deployed soon after completing endurance testing.

Please contact us to learn more about how we can be your equipment solutions provider for your current and future operational requirements. Greg Leos - VP

Letter From Len

Help Others Become Successful:

Success is not too complicated; you have "to get things done." Do it yourself or ask for help or give help; these are the three ways to get it done.

Obviously, doing everything yourself produces less than getting help or giving help. You can only become successful as your own time and efforts allow.

Outstanding success comes through expanding efforts through others. Have you heard the saying "to have a friend, you must be a friend"? This is sort of the concept.

Helping others be successful, and then they help you when you need it. It may sound corny, but it sure makes life more enjoyable. A fellow named Clint, whom I worked with early on in my oilfield life, helped me with everything. I did my best to help him back, but I always felt he did more for me. He was so talented at fixing things and so confident at work, and I grew stronger just by associating with him.

In a company, the boss should help those working for him, and all those should help the customer be successful.

Just help them. Len Freemyer - President

QUICK HITS

History:

Snake Hollow Gusher:

The “Snake Hollow Gusher” of McKeesport, Pennsylvania, revealed a natural gas field that soon attracted hundreds of exploration companies. Drilled near the Monongahela River southeast of Pittsburgh, the discovery well produced 60 million cubic feet of gas a day. The drilling frenzy it inspired resulted in $35 million invested in a nine-square-mile area. “Many residents signed leases for drilling on their land,” the local newspaper reported. “They bought and sold gas company stock on street corners and in barbershops transformed into brokerage houses.” AOGHS

The Father of Route 66:

Cyrus Avery, the "Father of Route 66," arrived in Oklahoma in 1897, initially selling life insurance in Oklahoma City. In 1908, during the Tulsa oil boom, he founded the Avery Oil and Gas Company. By 1916, after calling Tulsa a "little town without lights" with "pigs running loose in the streets," he played a key role in creating Route 66, championing the state road plan and national highway numbering system for the iconic Chicago to Los Angeles route.- AOGHS

Double Cementer with Redundant Hydraulic Systems which helps eliminate interruptions

Equipment Solutions

FIP takes great pleasure in providing exceptional unit upgrade services and solutions.

Two (2) higher-rated diesel engines

Redundant Hydraulic System

Plumbing Redundancies

Four (4) additional centrifugal pumps

Two (2) densitometers (mixing densitometer and downhole densitometer)

A new FIP Control Operating System has been installed - the Data Acquisition and Remote Monitoring

By collaborating with FIP, we can effectively help reduce your costs and make well-informed decisions that will have a positive impact on your financials.

Let Us Help Will All Your New Or Used Equipment Needs

FIP

Electric Solutions - REDEEM GREEN®

Fracturing

Stimulation

Cementing

Specialty Pumping Units

Electronics & Data Acquisition Solutions

Offshore Solutions

Pumps for CTU Support

Rebuild, Refurbishment, Restoration

After Sales Support

Fire Suppression Systems

July 2023 Information Journal

Currently, several new Dual Electric Blenders are being tested

Dual Electric Blender on Test Pad

Greg’s Guide

Currently, several new Dual Electric Blenders are being tested, as shown in the referenced picture. Utilizing a Trailer-Mounted Genset with a prime power of 1,825 kW is generating 480V. For this application, a 13,800V step-up transformer is being utilized for the necessary input power to the unit(s). FIP has the flexibility to change the configuration based on input power requirements.

To help avoid non-productive utilization of equipment, endurance testing is an important phase of Freemyer Industrial Pressure's process, which is crucial to identify possible abnormalities that may unexpectedly surface post-delivery. Our testing facility is equipped to pull full horsepower for fracturing units at various rates and pressures. Cooling towers are installed to allow for prolonged periods of testing on high horsepower equipment, and remote viewing of live testing operations is available for clients unable to be present.

The testing setup can support conventional diesel-powered equipment, dual-fuel-powered equipment, and electric-powered equipment.

To learn more about our Electric Blenders, Electric Cementing Equipment, and Patent-Pending Electric Unit design, please contact us. We would appreciate the opportunity to provide a custom solution for your operations for both conventional or electric-powered equipment

Stick’s Box

In various environments, oil and gas equipment is found, and one thing remains at the top of the list: safety. It's a never-ending system of constant improvement, measured every second of every day. The variables are vast, and the amount of safety consideration is overwhelming. I want to focus on one circuit that may or may not be on equipment deployed everywhere: the Positive Air Shutoff. This device, if properly maintained, can potentially save lives and equipment. It's a very useful tool to deploy in the event of any emergency. These devices are not maintenance-free and should be exercised regularly. If defective, they must be immediately repaired.

The very first things tested on equipment I had moving through the job-ready checkout were always safety features. This included fire systems, how quickly it could be neutralized, its speed when going to idle, and, of course, the positive air shutdown device. No matter which piece of equipment it was, if it had a combustion engine, it had to have this safety feature.

I am writing this now because I became complacent and failed to check the functionality of a positive air shutoff device for a client. I had assumed it worked. While commissioning the unit, I found out it didn't. All the years I have fully supported and acknowledged this great device went right out the window. It could have been deployed, and in the event of an emergency, it could have failed. I must send a big "Thank You" to Jerad Shaff for checking these devices and ensuring they operated as intended before deploying the equipment to the field.

Throughout all day-to-day maintenance and upkeep, don't assume anything and exercise these devices. Even though they may be in some hard-to-access areas, the time taken to do so is invaluable. Heston Starkey – Ops Manager

Letter From Len

This past April was Len Freemyer’s 35th year in business.

It all began with Freemyer Inc., where 5 divisions of different types of services related to oil and gas, mining, and refining businesses spun off from the original Freemyer Inc. This startup was in April of 1988 in Odessa, Texas, which we know as the heart of the Permian Basin.

Manufacturing is the focus of the company today, with leading products for the industry. Freemyer Industrial Pressure has equipment in 27 countries, and I do my best to stay involved with all projects.

I (Len) believe my purpose today is to be empathetic to our clients' needs and problems, as well as those that work for the company. I am disappointed at times when we have been slow to solve a problem or develop a solution for our clients or the people at Freemyer.

We have certainly had our ups and downs in all areas, but I am very proud of our shops today. They are all clean and professionally kept, and our people are outstanding. They are the core and heart of this outfit, and I thank God for them.

My wish for the future would be to improve in all areas of simplicity but be stronger and longer-lasting with less maintenance. Then have service faster than lightning to solve problems in this complex world of Electronics and technically advanced equipment. - Len Freemyer (President)

QUICK HITS

History:

“Iron Pipeline”:

On August 1, 1872, the Iron Pipeline delivered Pennsylvania Natural Gas, the first large-scale delivery of natural gas by pipeline. Gas was sent to over 250 residential and commercial customers in Titusville, Pennsylvania, home of America's first oil well drilled in 1859. The two-inch iron pipeline transported the natural gas five miles from a well producing four million cubic feet daily. The Keystone Gas & Water Company constructed the pipeline, aiming to deliver gas from a record-breaking well. This historic gas well continued production until the 1880s, according to the Drake Well Museum and Park in Titusville.- AOGHS

La Brea Asphalt Pits:

La Brea pits were discovered during a 1769 Spanish expedition on the West Coast. The pools contain sticky asphalt, not tar, and have been seeping crude oil for over 40,000 years. Native Americans used this substance for waterproofing. Outside the Page Museum in Los Angeles, life-size replicas of extinct mammals from Rancho La Brea are featured. - AOGHS

FIP

Electric Solutions - REDEEM GREEN®

Fracturing

Stimulation

Cementing

Specialty Pumping Units

Electronics & Data Acquisition Solutions

Offshore Solutions

Pumps for CTU Support

Rebuild, Refurbishment, Restoration

After Sales Support

Fire Suppression Systems

Reconditioned Frac Pumper

Equipment Reconditioning

FIP takes great pleasure in providing exceptional unit reconditioning services. We would like to take this opportunity to showcase one of our exemplary units and to inform you that we will have a total of thirty-one (31) Frac units available.

These units can be rented while we carry out reconditioning or routine maintenance on your existing equipment. It is noteworthy that among these units, ten (10) are Dual Fuel (DGB) units. These units will also be available for purchase.

In addition to the Frac Units, FIP has two (2) 120 BBL Blenders ready for immediate deployment.

The blenders can be utilized to sustain your operations while your own blender is being serviced or reconditioned. By collaborating with FIP, we can effectively help reduce your costs and make well-informed decisions that will have a positive impact on your financials.

Reconditioned Frac Pumping Unit with Mixing Tub

June 2023 Information Journal

Upgrading Existing Assets

Upgrading the major components of existing assets to increase performance is ideal, as it not only lowers the upfront costs but also decreases completion times. Although major component deliveries, specifically the engine and transmission powertrain, are starting to improve, upgrading existing assets has its advantages. Other advantages include the ability to utilize and restore some existing components such as the trailer chassis, engine, transmission, and control system, typically with new cables and sensors. Additionally, there are benefits reflected in the financial statements and balance sheet, as the older legacy assets are either in or nearing scheduled depreciation. Lowering the initial cost of restoration compared to new build costs helps facilitate a quicker return on investment, enabling the equipment to be deployed faster and generate revenue with its revitalized performance.

Some clients prefer to undertake their equipment readiness projects in batches. For example, a recent project involved several fracturing units that were originally configured with a Horizontal Cooling Package, MTU 12V4000 Engine with CAT Transmission, equipped with a 2250 HP Triplex Pump Assembly. The upgrades for this project included a new Cube Style Cooling Package, servicing of the Engine and Transmission, installation of a new 3000 HP Quintuplex Pump Assembly. Also, an upgrade to the Fan Drive System that eliminated the existing potentially problematic driveline assembly by installing a direct-drive Hydraulic Fan Pump System.

Whether you are considering a fleet of equipment or upgrading single units at a time, please contact us to discuss the level of upgrade, restoration, and the approach to optimize your equipment. FIP is focused on providing solutions to help reduce your initial cost of ownership and facilitate a prompter return on your investment. - Greg Leos (VP)

Stick’s Box

There's no question in pumping applications: which component fails the most? The actual pump. It is the part of the system that converts all the horsepower and torque into the force required to move the reluctant proppant or slurry through the network of high-pressure piping and directs it into the well and beyond.

This pump, as we call it, is subjected continually to severe levels of abuse, be it on a torsional level due to never maintaining the torsional damper, simply not maintaining fastener torque, a warped or failing unbalanced driveshaft, bad components in the fluid ends—the combinations are endless, right down to the pump base design, which is usually the most rudimentary item on the unit; actually, transmitting bad things into the pump instead of helping to remove them, after all, the torsional damper is only there for so much if there is one.

Most of these failures are blamed on crazy stuff, like, "All the bull gear bolts broke off, they must be a bad batch" or "These connecting rod bolts failed; they must have not been torqued right. Should have used red locking juice." Just imagine the failures coming from or being induced into the pump from elsewhere. You may surprise yourself with what you find. We all know it's hard to rewind beyond a point of failure to see what happened. Often the conclusion drawn is the wrong one, and the system repaired or installed is subject to the same forces that failed the previous. After all, all failures are learning experiences. - Heston Starkey (Ops Manager)

Letter From Len

Help Others Become Successful: Success is not too complicated; you have "to get things done." Do it yourself or ask for help or give help; these are the three ways to get it done.

Obviously, doing everything yourself produces less than getting help or giving help. You can only become successful as your own time and efforts allow. Outstanding success comes through expanding efforts through others. Have you heard the saying "to have a friend, you must be a friend"? This is sort of the concept.

Helping others be successful, and then they help you when you need it. It may sound corny, but it sure makes life more enjoyable. A fellow named Clint, whom I worked with early on in my oilfield life, helped me with everything. I did my best to help him back, but I always felt he did more for me. He was so talented at fixing things and so confident at work, and I grew stronger just by associating with him.

In a company, the boss should help those working for him, and all those should help the customer be successful. Just help them. Len Freemyer (President)

QUICK HITS

History:

Phillips Petroleum Company:

Phillips Petroleum Company was founded in Bartlesville, Oklahoma during the early months of World War I. The company grew rapidly, with assets increasing from $3 million to $100 million within a few years. In 1927, they started selling gasoline and eventually established over 10,000 Phillips 66 service stations. Their high-octane aviation fuel played a crucial role in World War II. – AOGHS

First New Mexico Oil Well:

In 1922, New Mexico's first commercial oil well was drilled near Shiprock by the Midwest Refining Company. The Hogback No. 1 well and subsequent wells in the area established the Hogback oilfield as a significant producer in the San Juan Basin. A pipeline to Farmington was completed two years later, allowing oil to be shipped by rail to Salt Lake City for refining.

FIP

Electric Solutions - REDEEM GREEN®

Fracturing

Stimulation

Cementing

Specialty Pumping Units

Electronics & Data Acquisition Solutions

Offshore Solutions

Pumps for CTU Support

Rebuild, Refurbishment, Restoration

After Sales Support

Fire Suppression Systems

Trailer Mounted Fracturing Units

Cooling Package Changed to Cube Style Radiator Assembly

Servicing of Powertrain – Engine & Transmission

Upgraded to 3000 HP Quintuplex Pump Assembly

Power End Lubrication System Upgrade

Hydraulic System Upgrade

New Hose Assemblies Installed

Please contact us to discuss what level of upgrade, restoration, and approach to optimize your equipment.

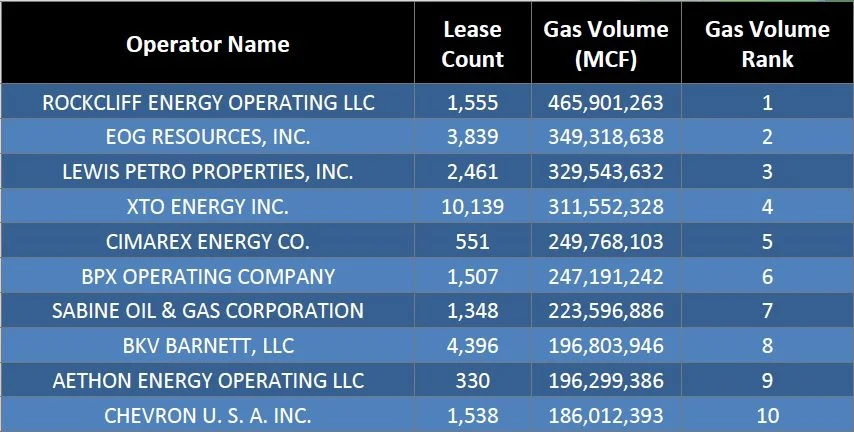

2022 Texas Production Ranks by Operator (Gas)

*Source: Railroad Commission of Texas

May 2023 Information Journal

Dual Electric Blender

Freemyer Industrial Pressure LP - Patent Pending: New Dual Electric Blenders will be deployed soon, with several in the final phases of production.

This Dual Electric Blender will enable service companies to perform Dual Frac Operations, Simulfrac Operations, or Split Stream Operations at well sites due to the built-in redundancy of major components. These built-in engineered redundancies on a single trailer can also serve as a backup blender, reducing the footprint on location with one (1) less tractor and one (1) less trailer-mounted blender.

The design allows for one (1) or two (2) separate and independent tub operations. During operations, field engineers may vary proppant concentrations throughout the job without affecting the other zone(s) and run separate job design recipes altogether, depending on how the well zone(s) are responding, and then make real-time adjustments for optimal well performance.

Increasing efficiencies and performance benefits our service company clients and their end clients - E & P companies - to improve fracturing programs.

Please contact us to schedule a visit at our Fort Worth Facilities to review the various engineered solutions that range from Dual Electric Blenders to Simulfrac Blenders. Service companies, E & P companies, and their respective engineers are welcome to attend to learn more. Greg Leos – VP

Stick’s Box

Ease of maintenance is key. It's widely known that if it's hard to access, it won't be attended to. Don't settle for hidden items that require routine service. Take the time to relocate them or have them placed for easy maintenance in the future.

There's absolutely no reason to conceal filters or any item that needs inspection or maintenance. Keep it at ground level if possible and ensure it's easy to service with no environmental impact.

All equipment starts life the same and is handed off to the people who service and maintain it. Remember, if it's difficult to access, it probably won't receive the necessary attention. (Heston Starkey)

Letter From Len

When I was young, I heard this: "To have a friend, you must be one."

I believe the greatest emotions we experience are the need to be wanted, needed, and loved. Being kind to others is always possible, even if we do not necessarily love them. When we maintain a positive attitude, we attract others to us, but when we are negative, we repel them. Letting people know they are important can be done by giving compliments, writing letters of gratitude, and offering praise, encouragement, and support. Cooperation can help to change our relationships.

While it is important to stand up for our rights, do we always have to be right? Consider whether it really matters and whether it will impact what is truly important. Best wishes, Len Freemyer (President)

QUICK HITS

History:

“Mr. Charlie”:

In the Gulf of Mexico, a Kerr-McGee drilling platform, the Kermac Rig No. 16, in 1947 became the first offshore rig in the Gulf of Mexico that was out of sight of land. By the end of 1949, the Gulf’s offshore industry had discovered 11 oil and natural gas fields. Constructed in a New Orleans shipyard, in 1954 the barge drilling platform Mr. Charlie became the world’s first mobile offshore drilling unit (MODU). - AOGHS

Patent for perforating Well Casing:

Circa 1937: Ira McCullough of Los Angeles patented a multiple bullet-shot casing perforator and mechanical firing system. He explained the object of his oilfield invention was “to provide a device for perforating casing after it has been installed in a well in which projectiles or perforating elements are shot through the casing and into the formation.” - AOGHS

FIP

Electric Solutions - REDEEM GREEN®

Fracturing

Stimulation

Cementing

Specialty Pumping Units

Electronics & Data Acquisition Solutions

Offshore Solutions

Pumps for CTU Support

Rebuild, Refurbishment, Restoration

After Sales Support

Fire Suppression Systems

Newly built or upgrade your existing Double Cement Units with increased power and redundant hydraulic systems with data acquisition configured for wired or wireless monitoring.

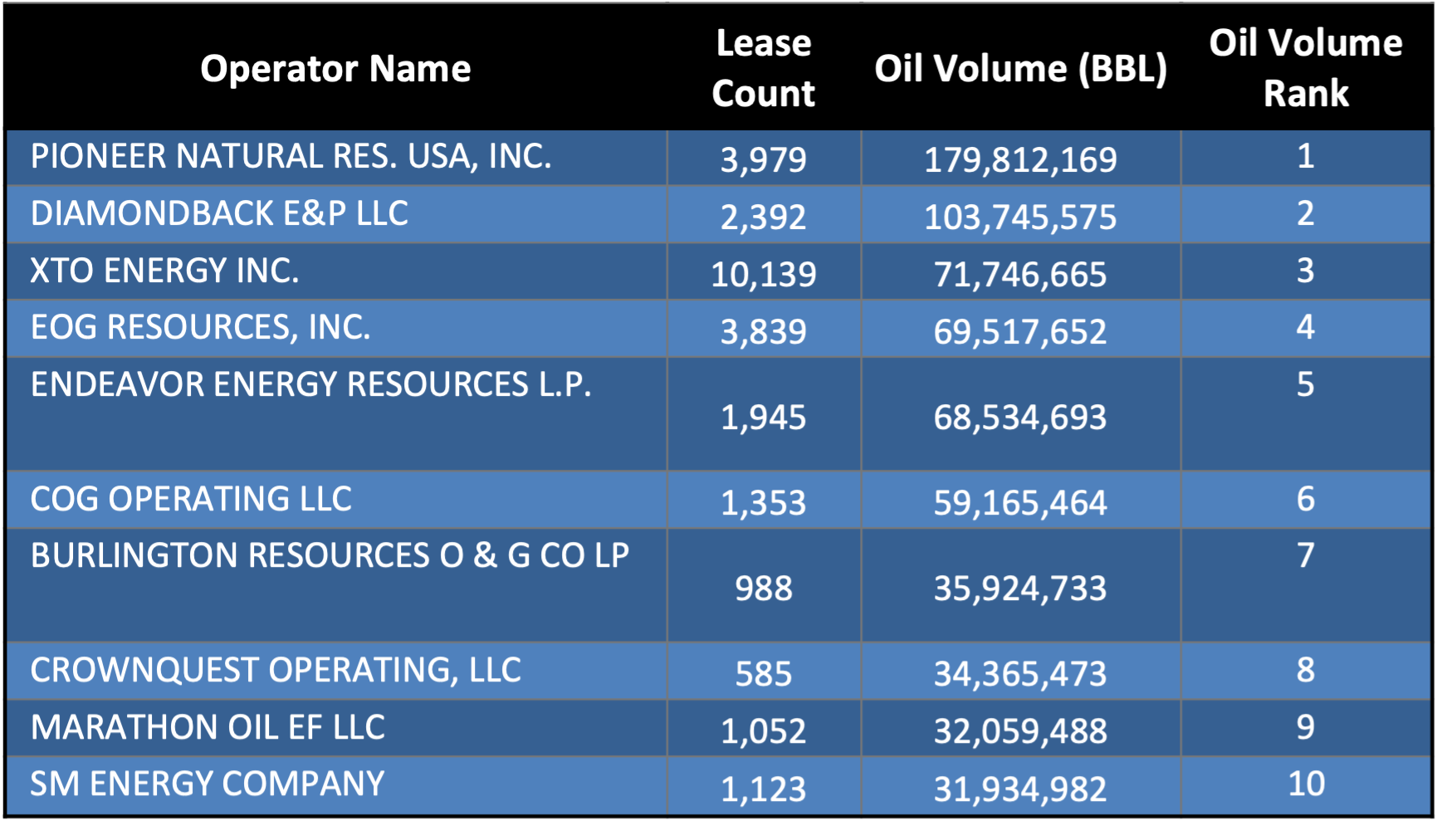

2022 Texas Production Ranks by Operator (Oil)

April 2023 Information Journal

Solutions to Help Reduce Non-Productive Time

Laterals are getting longer, and equipment needs to be engineered to manage multiple operations and fields.

Equipped on our next generation Double Cement Pumping Units are two (2) higher rated diesel engines. Each engine has a redundant hydraulic system and eliminated a third auxiliary hydraulic engine. Each hydraulic system is designed to operate the entire system, which translates to no centrifugal power losses and more importantly, no interruptions to mixing operations. This configuration helps maintain productive time in the field.

Redundancies incorporated into the design – from plumbing, centrifugal pumps, and two (2) densitometers (mixing densitometer and downhole densitometer). The FIP Control System is equipped with mixing water valve control, dry cement inlet valve control, tub level, and real time data acquisition for remote monitoring; and parameter exporting for third party system design modeling software.

Whether upgrading your existing equipment or newly built equipment FIP will be here to help provide solutions. (Greg Leos – VP)

Stick’s Box

Engine crankshaft endplay is crucial to the life of equipment. Endplay should be checked periodically or anytime a new component is replaced or serviced, such as fan pump drive shaft, torque convertor, simple front, or rear seal replacement. These engines rely on a film of oil that continually has to be replenished, to lubricate a space of 4/1000 of an inch. Pressure on the fore and aft of crankshaft will quickly diminish the clearance, restricting the chance of oil to properly lubricate and cool those surfaces.

Driveshaft fan drives are the best at killing engines if strict maintenance isn’t followed for the driveshaft. Keep the slip and universal joints well lubed and in proper working condition, have balance checked and replace periodically, if the slip binds up it will force the crankshaft against its thrust bearings, which will fail the engine in short order. (Heston Starkey – Ops Manager)

If the time comes for engine renew or overhaul, please have these small items heavily scrutinized and or replaced, you might learn that they played a hand in some of the wear and or failure of the engine.

Leadership Is an Action

Years ago, I attended a Dave Ramsey conference in Nashville. A couple of things that stick in my mind from the conference are, "You are not a leader unless people want to follow you," and "A great leader has empathy and shows caring in action to those in need." I am told that Ramsey considers empathy an important quality of new hires, and without it, they do not get hired.

It does take time to care, and I believe that people are worth it. When we lose someone after investing time to train them, it costs us money. That is money we could use to improve our company, so we take it seriously at FIP. We care about our company adapting to the changing industry so that we are still profitable and able to provide for our company families. Thus, we have patented electric blenders and pumps, including all well-service pumps.

We wish you success and contentment both at home and at work. (Len Freemyer - President)

Around The World

April 13 – 15: Songkran, Thailand

The traditional Thai New Year Festival better known as the “Water Festival” were everyone is likely to get Super Soaked. The celebration is symbolic of “cleansing and purification” to mark the beginning of the new solar year.April 28: New Orleans Jazz and Heritage Festival

The city of New Orleans boasts a lively music scene that remains bustling throughout the year. However, during the annual Jazz Fest, a jubilee that celebrates local music and culture, the scene becomes exceptionally vibrant. This grand event draws in a significant audience with performances from both renowned headliners and local talents, making it a spectacular spectacle.April 30: Beltane Fire Festival, Edinburgh

The festival is an annual celebration of Gaelic tradition dating back to the Iron Age. It's a boisterous event that culminates in a massive bonfire on Calton Hill. Fire was considered a healer and a purifier, and the bonfire symbolizes a fresh start for the new season.

QUICK HITS

Thought of the Month:

“No man ever steps in the same river twice, for it is not the same river and he is not the same man” - Heraclitus of Ephesus

History:

American Petroleum Institute founded:

Tracing its roots to World War I when the petroleum industry and Congress worked together to fuel the war effort, the American Petroleum Institute (API) was founded in New York City. Within two years, the organization had improved an 1876 French scale to measure petroleum density compared to water — a standard later adopted and called API gravity. (AOGHS)

Oklahoma City’s “Wild Mary Sudik”:

What would become one of Oklahoma’s most famous wells struck a high-pressure formation about 6,500 feet beneath Oklahoma City and oil erupted skyward. The Indian Territory Illuminating Oil Company’s Mary Sudik No. 1 well flowed for 11 days before being brought under control. It produced about 20,000 barrels of oil and two hundred million cubic feet of natural gas daily — becoming a worldwide sensation. (AOGHS)

FIP

Electric Solutions - REDEEM GREEN®

Fracturing

Stimulation

Cementing

Specialty Pumping Units

Electronics & Data Acquisition Solutions

Offshore Solutions

Pumps for CTU Support

Rebuild, Refurbishment, Restoration

After Sales Support

Fire Suppression Systems